Do you use polyurethane rigid foam in your production?

Are by-products from polyurethane rigid foam generated during your production process?

Are your transport and disposal costs for by-products from polyurethane rigid foam high because the product is very bulky?

There is another way.

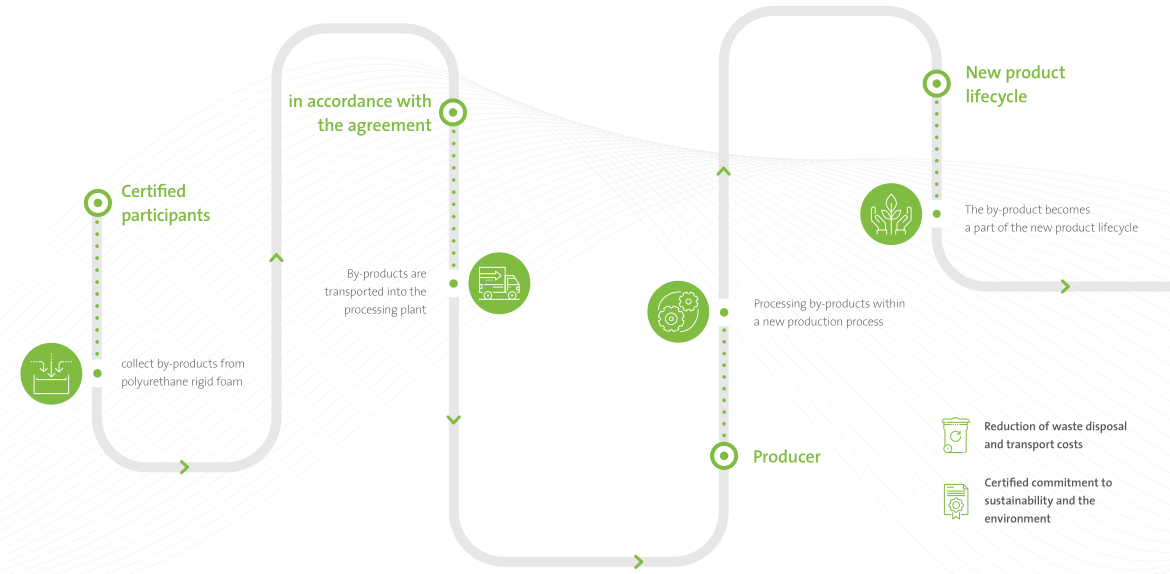

Return by-products from polyurethane rigid foam generated in your production process back into the production cycle and save disposal and transportation costs.

Make a lasting commitment to the environment and the protection of resources. By-products from polyurethane rigid foam generated in your production process, may already be used tomorrow in the production of new products.

Demonstrate your company commitment to to sustainability and protection of the environment. Companies participating in NEXT STEP PU receive a certificate for their participation and may use it to their advantage for advertising purposes.

Agent of NEXT STEP PU is the puren company. The company is concretely committed to sustainability and environmental protection.

NEXT STEP PU was created initially for the company?s own use and was later extended to other producers choosing to supply their high quality by-products from polyurethane rigid foam to a new product lifecycle.

Companies participating in the NEXT STEP PU contribute actively to sustainability, protection of our environment and preservation of resources. Your participation in NEXT STEP PU may be used to enhance your market presence.

The quality of the by-products from polyurethane rigid foam correspond to the contractual agreements for the participation in NEXT STEP PU. For the by-products the following quality requirements must be:

For the transportation of polyurethane by-products various logistics solutions are available such as offcuts, flour, or briquettes.

Waste material sacks. Collection at the place of origin. Delivery or collection according to contractual agreements. Suitable for small pieces and smaller quantities. The only costs incurred are transport and packaging costs.

Panel-like formats, wrapped with PE foil on a pallet. Delivery or collection according to contractual agreements (trucks, weighed by load). Only transport and packaging costs are incurred.

Big Bags (also for higher weights). Compressed as briquettes or in loose form, such as chips, milling dust. Big-Bags on pallets are disposable packages and must be provided by the producer. Higher costs for packaging/transport and discharge. Suitable for medium-sized quantities.

Roll-off container. Automatic compression and collection. A collection point for at least one container and a storage place for a switch container are required. Regular intervals, plannable, and contractually agreed. Coordinated logistics.

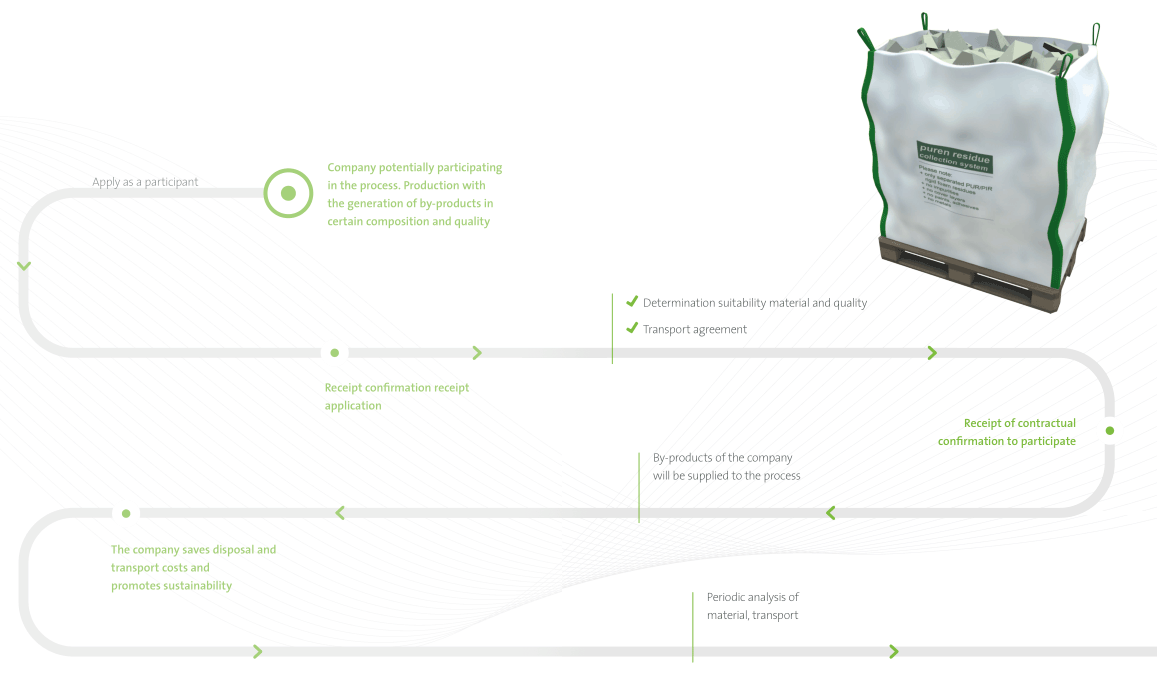

Participation in the NEXT STEP PU is contractually agreed upon. Use the form below to apply to participate.

puren gmbh

Rengoldshauser Str. 4

88662 Überlingen

Germany

Phone +49 (0) 7551 80 99–0

Fax +49 (0) 7551 80 99–20

verwertung@puren.com

en.puren.com